Email Us :contact@ionic.co.in

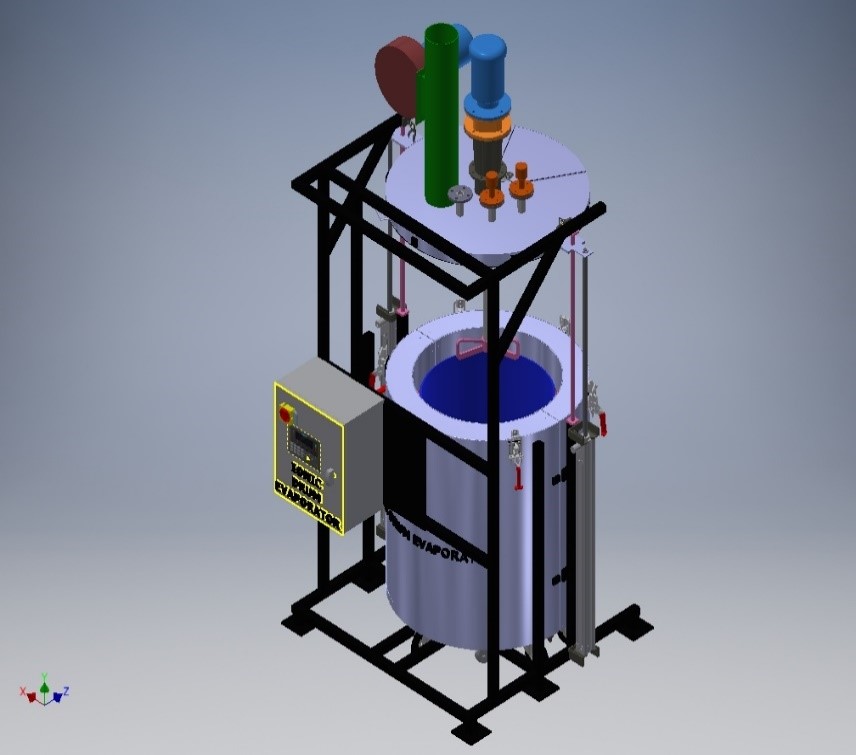

IONIC offers the ‘EASY DRY” Drum Dryer for dewatering concentrated slurries and sludge to a dry landfillable (see NOTE below) condition. These systems are electrically heated, operate in batch mode, and are controlled on a time and temperature basis. Typical applications include bottoms from Zero Liquid Discharge Thermal evaporator, concentrate from MVC Evaporators, concentrated salt slurries, viscous solutions such as water-based inks and paints, other water based sludge applications.

The EASY DRY Drum Dryer Advantages

The Drum Dryer Advantages

1. Constant circular and vertical mixing of sludge or slurry to ensure homogeneous drying.

2. Drum can also be the disposal vessel to minimize handling.

3. Timer controlled to avoid over drying.

4. Temperature controlled for safe drying.

5. Pneumatic lift system to easily remove mixing system from drum.

The EASY DRY Drum Dryer completely encapsulates a standard 200 litres capacity drum of sludge or slurry and heats it from outside the drum. Since the heating elements do not contact the sludge or slurry there is no requirement to clean the heat transfer surface. Temperatures are controlled with a thermocouple and timer system to provide consistent heating and accurate level of dryness. Hi torque motor and gear reducer provide gentle and consistent agitation even as solutions become more viscous and solid.

Pneumatic lifting system allows easy removal of lid and agitator system at completion of drying. Hinged clamshell walls along with pneumatic lifting system allow easy removal of drum and dolly for loading and unloading.

NOTE : Determination of whether or not dried residue is landfillable is responsibility of the customer and should be done in accordance with local, state, and federal regulations. IONIC does not imply or suggest that dry condition is sole requirement for disposing residue in landfill or other unregulated disposal facility.

Capacities & Dimensions

The EASY DRY Drum Dryer is designed with the following features:

- Low speed/high torque 316SS mixer OR Pneumatic Impulse mixer

- Pneumatic lifting system with mechanical safety latch for lid/mixer assembly.

- Micro safety switch to lockout heater and mixer when lid/mixer assembly is in raised position.

- Hastelloy C type J thermocouple

- Programmable temperature controller with digital display

- Programmable cycle timer with digital display.

- 316 L Mist Eliminator

- 4 inch ceramic fibre insulation in clamshell walls

- 2 inch ceramic fibre insulation in lid.

- Illuminated power on and drum dryer mode selector switches.

- Disconnect switch on control panel door.

- Drum dolly with industrial grade casters.

Dimensions and Specifications

- Drum Dryer Dimensions : 66 x 62 x 103 inches in open position (L x W x H)

- Drum Dimensions : 23 inches (D) x 35 inches max (H)

- Drying Rate: Variable based on application.

- Drum Dryer Stack Dimensions: 5 inch diameter x 25 foot max. straight vertical length

- Drum Dryer Volumetric Airflow: 120-200 CFM at 70F and 0.2 inches of water column

Features

- Hi Torque/Low Speed 316SS Mixing system

- Pneumatic Lifting System with Mechanical Safety Latch and Microswitch interlock with heaters and mixer

- Hinged clamshell walls with latching handles.

- Cycle Timer and Digital Temperature Controller both with digital display

- Heat transfer surfaces do NOT contact sludge and/or slurry

Benefits

- Consistent and homogeneous drying.

- Minimizes operator intervention with safe and reliable technology.

- Along with pneumatic lifting system provides easy access to drum.

- Dual control system to maintain consistent drying temperature and control over drying.

- Eliminates need to scrape or otherwise clean heat transfer surface thereby minimizing manpower requirement.

Applications

- Air scrubber wastewater solution - Water and Wastewater

- Compressor condensate wastewater treatment - Water and Wastewater - Water Treatment

Dye penetrant wastewater treatment - Water and Wastewater - Water Treatment

Ink, Paint, and Glue wastewater solution - Water and Wastewater - Landfill leachate wastewater treatment - Water and Wastewater - Water Treatment

Metal finishing wastewater solution - Water and Wastewater - Parts cleaning wastewater solution - Water and Wastewater

- Plating rinse wastewater solution - Water and Wastewater

- Using evaporation to dewater Reverse Osmosis reject waste streams - Water and Wastewater - Water Treatment

- Zero Liquid Discharge wastewater solution - Water and Wastewater

Planning for a project ?

Get in touch with us.. We love to serve you..

Call : 020-27475272 / 8275486263 or Write to us

Copyright ©. Ionic. All Rights Reserved Login Sitemap Privacy Policy