Email Us :contact@ionic.co.in

- Bar Screens

- Tubular Membrane Filtration System

- Physio Chemical Treatment System

- Biological Treatment System

- Membrane Based Treatment System

- Advanced Oxidation Systems

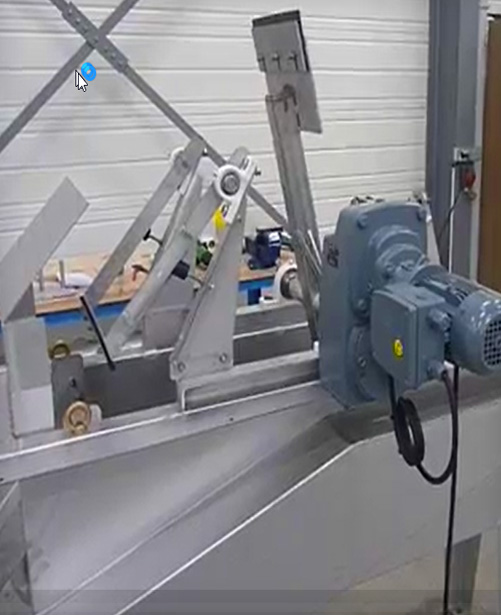

Bar Screens

A bar screen would be required to screen particles and removes all the bigger particles from the Sewage and waste water. This waste should then be collected and disposed as solid waste into municipal waste collection/ organic converter/ compost yard. We offer a automatic mechanical rotating bar screen system to automatically clean the bar screen. The system consistent of Arc type bar screen and a rotating brush with screens and the screen continuously or as and when needed. The removed solids are collected in waste bin for further disposal. The standard sizes available are 250/500/750/1000 mm.

A bar screen would be required to screen particles and removes all the bigger particles from the Sewage and waste water. This waste should then be collected and disposed as solid waste into municipal waste collection/ organic converter/ compost yard. We offer a automatic mechanical rotating bar screen system to automatically clean the bar screen. The system consistent of Arc type bar screen and a rotating brush with screens and the screen continuously or as and when needed. The removed solids are collected in waste bin for further disposal. The standard sizes available are 250/500/750/1000 mm.

Alternatively for small systems we provide manual bar screens.

Tubular Membrane Filtration System

IONIC manufacturers a range of tubular membrane filtration system for treating raw water, waste water. In most cases where these difficult pre-filtration conditions occur, the problem can be addressed with a microfiltration system using Tubular Membrane Filter (TMF™) Modules. The TMF systems are very similar to Reverse Osmosis systems, where a booster pump, piping, valves and TMF elements are mounted on a skid.

IONIC manufacturers a range of tubular membrane filtration system for treating raw water, waste water. In most cases where these difficult pre-filtration conditions occur, the problem can be addressed with a microfiltration system using Tubular Membrane Filter (TMF™) Modules. The TMF systems are very similar to Reverse Osmosis systems, where a booster pump, piping, valves and TMF elements are mounted on a skid.

Open Pond Water Having Algae, Suspended Solids, Tubidity and Organics - Tubular Membrane Module

Typically, between 75 and 95% of the water passes through as permeate and is sent to the RO or Nanofilter system. The concentrate is recycled up stream of the TMF Modules at the Concentration Tank for re-dilution. In operation, a fluid, such as chemically pre-treated wastewater, flows through the membrane tubes at high velocity, sufficient to maintain turbulent flow. At typical operating pressures of 20–80 psi, clean fluid is forced through the pores of the PVDF membrane, while suspended particulates remain in the retentate stream. The turbulent flow of the retentate stream prevents the build-up of particles on the inner surface of the membrane tube, providing high flux and prolonged filter life. This turbulent cross-flow performance and large bore tubular design may eliminate the need for prefiltration and should routinely handle high solids levels up to 5% by weight. Solids concentration is kept at 3-5% with the excess solids sent to a filter press for de-wetting or to disposal. The number of Tubular Membrane Filter Modules required is dependent upon the total flow rate requirement of the system. The modules are typically placed in series, or train, of up to 12 modules and systems is usually designed to allow at least one train of modules to be independently taken off line for routine maintenance cleaning. To support system design, a small pilot test system can be used to determine capacity and identify any issues, such as colloids, that might require further module cleaning. Membranes are available in HDPE and PVDF for handling low temperature and high temperature applications.

Typical applications

- Raw water filtration

- Lime soda softening

- Heavy metals precipitation

- RO reject recovery

- Fluoride reduction

- Brine clarification and filtration in Chlor Alkali industry

Semiconductor fabrication waste water recycling - Designed specifically for:

- Wafer grinding

- Back grinding

- Solar panel and glass grinding

- Applications involving fine, abrasive particle removal

- Solar panel and Glass industry waste water recycling

Physio Chemical Treatment System

IONIC offers custom solution for physiochemical treatment of raw water and waste water. Industrial water discharge is regulated by government regulations and waste water containing oil, grease, heavy metals, inorganic and organic impurities needs to be removed prior to discharge in to land or surface water.

IONIC offers custom solution for physiochemical treatment of raw water and waste water. Industrial water discharge is regulated by government regulations and waste water containing oil, grease, heavy metals, inorganic and organic impurities needs to be removed prior to discharge in to land or surface water.

Depending on the nature of waste water impurities treatment scheme is carefully selected. The treatment scheme is divided in to primary treatment, followed by secondary treatment and tertiary treatment . Oil water separation, Neutralization, Heavy metals and objectionable inorganic substances like Fluoride, Nitrates, Phosphates etc. are precipitated by careful addition of chemicals. Coagulation and flocculation followed by solid liquid separation in a clarifier and tertiary treatment to remove fine suspended solids, organics and hydrocarbons is provided.

Many of the technologies and unit processes are carefully chosen to provide outstanding performance.

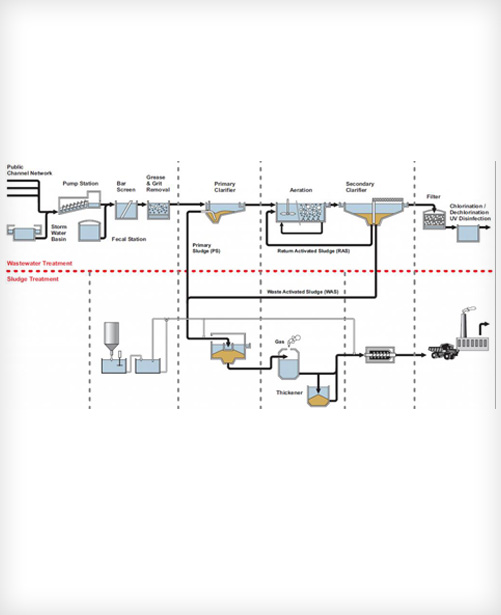

Biological Treatment System

This system consists of primary Clarifier, Aeration tank and Secondary clarifier to remove biomass. Fine bubble diffused aeration system is implemented for effective aeration of the biomass and to increase the Oxygen transfer efficiency and reduce operating cost. Optionally tertiary treatment system is provided to remove residual BOD, Suspended solids and turbidity and the final treated water is disinfected with Chlorine Dioxide.

This system consists of primary Clarifier, Aeration tank and Secondary clarifier to remove biomass. Fine bubble diffused aeration system is implemented for effective aeration of the biomass and to increase the Oxygen transfer efficiency and reduce operating cost. Optionally tertiary treatment system is provided to remove residual BOD, Suspended solids and turbidity and the final treated water is disinfected with Chlorine Dioxide.

Membrane Based Treatment System

The right treatment for your waste machine coolant treatment and disposal:

Importance of treating waste metal working machine coolants

Importance of treating waste metal working machine coolants

Machine coolants have definite service life after which it needs to be replaced. Waste metal working coolants have many impurities and contribute to high BOD, COD, heavy metals etc and cannot be discharged to the environment directly. Waste disposal cost is increasing day by day.

There are various ways to treat Oil soluble and Semi synthetic coolants. Ionic offers membrane based system to treat Soluble oil and semi synthetics to separate primarily free oil and emulsified oil.

What is in your waste machine coolant ?

More than 90% of the machine coolant is water.

Soluble Oil:- Contains 60-85% mineral oil and emulsifies in to water

Semi Synthetic:- Contains 5-50% mineral oil and emulsifies in to water

Fully synthetic:- Contains no mineral oil

Straight Oils:- Contains 70-85% mineral oil and is not water miscible

UF system removes oil. Surfactants and other organic and in organic additives pass through the membrane. This is removed in the post treatment system using either advanced oxidation or adsorption process depending on site specific disposal conditions.

Return on Investment

Cost of disposal of waste machine coolant is increasing day by day. Many companies send the waste coolant out to waste haulers at enormous cost without knowing that it is against pollution control board regulatory norms. Waste oil which is having > 80% oil content can be sent out for recycling whereas waste metal working fluids having low oil concentration (generally < 10%) cannot be sent out for disposal.

Presently the cost of hauling is over Rs.7.0 /litre of waste metal working fluid. It makes sense to reduce the waste volume and reduce the disposal cost.

In most cases the payback period will be less than a year when installing our system.

Besides the Capital costs and operating costs there are many other parameters that goes in determining the economics of operating a waste water treatment plant.

LIQUID FLUORESECENT DYE PENETRANT TREATMENT SYSTEM

Ionic provides CERAFLUX systems for treatment of Fluorescent Dye penetrant treatment system.

Treating, transporting and disposing of penetrant wastewater can be a time consuming and costly process for manufacturers and test facilities involved in the NDT inspection process. Continued tightening of environmental restrictions at both the federal and local levels has prohibited drain disposal of non pre-treated wastewater in all but a few locales making pretreatment the primary choice for those wishing to avoid the high cost of private disposal services. Of all the pre-treatment options available to manufactures none are more easy to install and economical to operate than the "CERAFLUX" treatment systems.

Treatment benefits

- Complete removal of colour caused by the presence of fluorescent dye

- Fully automatic operation

- Non chemical process

- Easy to operate

- Can handle fluctuations in feed characteristics

Typical applications

- Aerospace Industries

- Nuclear Industries

- Automotive Industries

Advanced Oxidation Systems

Is used When difficult to treat high COD waste water with refractory organics need to be removed

IONIC provide Advanced Oxidation Process (AOP) based solutions for the treatment of difficult to treat industrial waste water. Industrial waste water for example Pharmaceutical antibiotic destruction, Bulk Drug waste water, Condensate treatment , Pesticides, Agro Chemicals, Ammonia – Nitrogen removal, Textile waste water, Colour removal etc. are some of the typical applications in which AOP process is deployed.

IONIC provide Advanced Oxidation Process (AOP) based solutions for the treatment of difficult to treat industrial waste water. Industrial waste water for example Pharmaceutical antibiotic destruction, Bulk Drug waste water, Condensate treatment , Pesticides, Agro Chemicals, Ammonia – Nitrogen removal, Textile waste water, Colour removal etc. are some of the typical applications in which AOP process is deployed.

Advanced Oxidation process (AOP) is any type of process that generates sufficient amount of Hydroxyl radicals (OH-) to oxidise contaminants and result in water purification. There are a promising alternative to conventional treatment methods and sometimes only viable treatment for complex waste water containing a mix of various pollutants.

Reactive Oxygen Species consist of free radicals – superoxide radicals (O2 ), Hydroperoxyl radical (HO2), Hydroxy radicals (OH-) and Alkoxyl radical (RO-) and non-radicals Hydrogen peroxide( H2O2). Free radicals as is known as atoms or molecules capable of independent existence that possess one or more unpaired electrons. These radicals are very short lived compared to non-radicals because the electrons are not paired in orbitals as they have different spin directions. They have very high oxidative power and highly reactive and hence used for destruction of organics in to carbon di oxide.

Reactive Oxygen Species consist of free radicals – superoxide radicals (O2 ), Hydroperoxyl radical (HO2), Hydroxy radicals (OH-) and Alkoxyl radical (RO-) and non-radicals Hydrogen peroxide( H2O2). Free radicals as is known as atoms or molecules capable of independent existence that possess one or more unpaired electrons. These radicals are very short lived compared to non-radicals because the electrons are not paired in orbitals as they have different spin directions. They have very high oxidative power and highly reactive and hence used for destruction of organics in to carbon di oxide.

In the water industry hydroxyl radicals are considered to be the most important free radical generated via AOP. OH radical can be generated by various AOP processes including Fenton process, Photo Fenton process, O3- H2O2, Ozone –UV , H2O2 –UV, electro Fenton, BDD - Electrochemical Oxidation etc.

Fenton Process - Chemical Oxidation

This is a chemical process in which the pollutants are destroyed in acidic conditions with the help of Hydrogen peroxide in the presence of an Iron catalyst.

Photo Fenton - Photo Oxidation / Photo Chemical Oxidation

In the presence UV light OH radicals are generated. In some cases hydrogen peroxide is dosed to enhance OH radical production for complete oxidation of the organics.

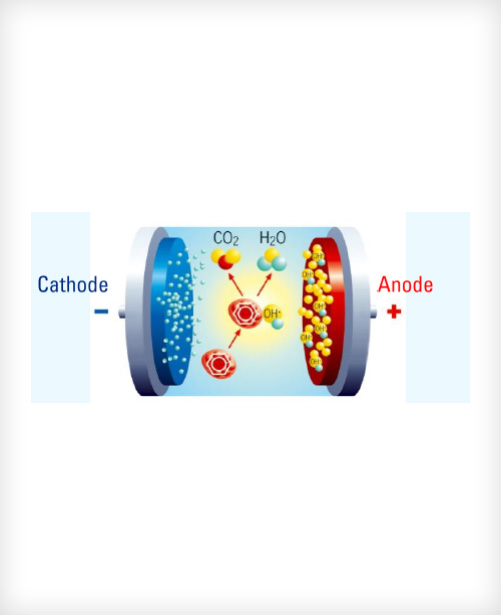

Electrox - Electro Chemical Oxidation

Electrooxidation is an electrochemical advanced oxidation process in which oxidation reactions occur by applying an electric field between the anode and cathode, it is designed to offer complete oxidation of all organic compounds to Carbon Dioxide (including persistent and toxic components) and Ammonium in to Nitrogen in water.

In this process the cathode and anode is coated with conducting chemically inert material. These materials have catalytic properties which allow the oxidation of the pollutants, either by direct contact with the anode, or by oxidation in the media.

The new design and special electrodes offer very long life and show a higher oxidation capacity than other advanced oxidation technologies. It also allows the disinfection of treated water "in situ" and the reuse of treated water is possible.

The application of this technique mainly causes the removal of :

- Soluble organic matter

- Volatile or semi-volatile Hydrocarbons

- Many of persistent organic compounds

- Colour and odour

- Nitrogen compounds (nitrate, ammonia)

- Free cyanide and inorganic cyanohydrins

- Treated water disinfection

- Specific toxins: CN, pesticides, herbicides, PCBs, phenols, fungicides.

- Active pharmaceutical compounds: oestrogen, cortisone, antibiotics, EDCs

- Elimination of bacteria, viruses and parasites

- BTEX and PAHs

- Sulphides, thiols and amines

Please contact us with your specific waste water characteristics and application to suggest you a suitable system.

Planning for a project ?

Get in touch with us.. We love to serve you..

Call : 020-27475272 / 8275486263 or Write to us

Copyright ©. Ionic. All Rights Reserved Login Sitemap Privacy Policy