The Future of Water Purity is Here

The Quick Cycle© Auto D.M. Plant

Drastically cut operating costs, eliminate manual processes, and ensure consistent high-purity water.

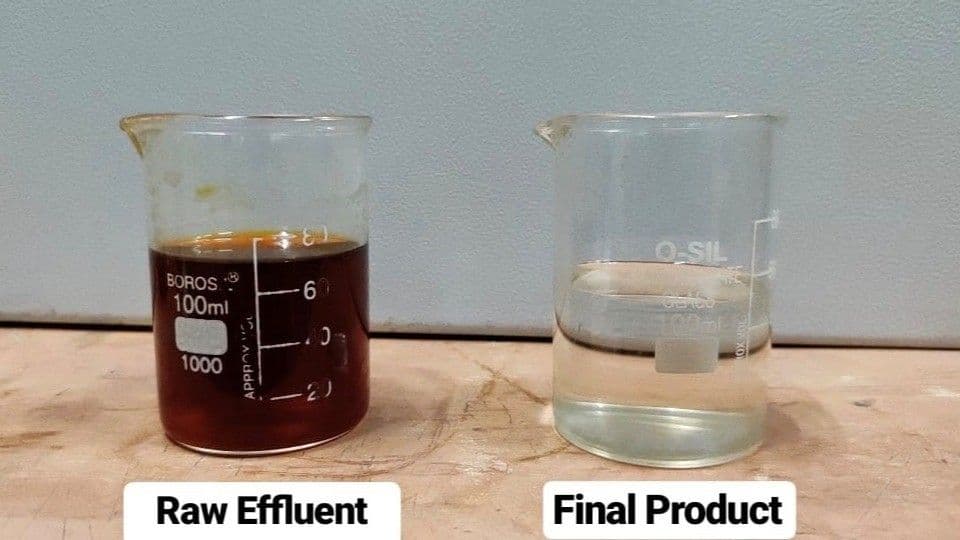

What is Demineralization and Why Does It Matter?

Demineralization is a water purification process focused on removing dissolved mineral salts and ions. Unlike simple filtration, it targets charged ions like Calcium, Magnesium, and Chlorides. The presence of these minerals in industrial processes can lead to scale buildup in pipes and boilers, causing severe inefficiency and costly damage over time. It can also compromise the quality and consistency of sensitive products like pharmaceuticals or semiconductors. Using demineralized (D.M.) water prevents corrosion, extends the lifespan of critical equipment, and ensures the final product meets stringent purity standards.

Key Industrial Applications

- Pharmaceuticals Industry

- Cosmetics Industry

- Chemicals Industry

- FMCG (Fast-Moving Consumer Goods)

- Automotive Industry

- Aerospace Industry

- Boiler Feed Water

- Battery Water

- Electronics & Semiconductors

The Problem with Manual Plants: Why You Need Automation

Traditional, manually operated D.M. plants are a major drain on resources, leading to high costs, significant wastage, and operational bottlenecks. The IONIC Quick Cycle© Auto D.M. Plant was engineered to solve these challenges.

High Labor Costs

Requires a full team per shift just to manage complex valve operations.

Extended Downtime

A single regeneration cycle can take 5-8 hours, halting production.

Significant Water Wastage

Outdated processes lead to massive wastage of rinse and drain water.

High Maintenance & Corrosion

Manual plants often use M.S. vessels that corrode and require constant upkeep.

A Clear Comparison

See how our Quick Cycle© Auto D.M. Plant completely outperforms conventional manual systems.

❌ Conventional Manual Plant

✅ Quick Cycle© Auto DM Plant

Operation & Manpower

Manual Plant

Full team required (Operator, Labor, Supervisor) for 27+ valve operations.

QCDM Plant

Minimal attention needed. No manual valve operations required.

Efficiency & Regeneration

Manual Plant

Slow 5-8 hour regeneration. High wastewater output (>41 M³).

QCDM Plant

Rapid 35-45 min cycle. 14 times less wastewater (2.75 M³).

Water Quality

Manual Plant

Requires a separate, cumbersome mixed bed unit for high purity.

QCDM Plant

Achieves mixed bed quality without the extra unit, simplifying operations.

Maintenance & Durability

Manual Plant

Corrosion-prone M.S. vessels need frequent painting & heavy maintenance.

QCDM Plant

Non-corrosive FRP vessels require virtually no maintenance.

Installation & Space

Manual Plant

Huge footprint (5x14 M) plus costly civil work for foundation/sump.

QCDM Plant

Compact footprint (2x1.5 M) with no extra civil work needed.

Total Annual Savings

Manual Plant

High recurring costs for labor, water, chemicals, and upkeep.

QCDM Plant

Significant cost reduction as compared to manual plants.

Technical Resources

Download detailed specifications and engineering data.

Quick Cycle© Auto DM Plant

Our Network

Trusted by Industry Leaders

Partnering with global organizations to deliver sustainable engineering excellence and innovative water and waste water treatment solutions.

Frequently Asked Questions

Common questions about the Quick Cycle® Auto D.M. Plant.

Still have questions?

Contact our support teamThe Quick Cycle® system completes regeneration in just 35-45 minutes, whereas conventional manual plants typically require 5-8 hours. This drastically reduces downtime and increases water availability.

No. The system is fully automated and eliminates the need for manual valve operations (which can involve 27+ valves in manual plants), thereby reducing labor costs and potential for human error.

The Quick Cycle® Auto D.M. Plant is highly efficient, generating only ~2.75 m³ of wastewater per regeneration cycle, compared to over 41 m³ for a typical manual plant—delivering approximately 14x water savings.

No. The system is engineered to deliver high-purity water (Mixed Bed Quality) directly from the primary unit, eliminating the need and cost of an additional Mixed Bed polisher.

Latest Insights

Get in touch with our experts

Have a custom requirement? Book a free consultation with our engineering team or drop us a message.

Contact Information

Call Us

020-27475272/73

020-29525874

+91 82754 86263

Mon-Sat, 9:30 AM to 6:30 PM

Visit HQ

S. No. 1, 5, 11-13, B Wing,

Mahalaxmi Heights, Mumbai-Pune Rd,

Pimpri, Pune-18, MH, INDIA.