Pharma Grade Water Systems

High Purity Water (HPW) & WFI Generation

USP/EP Compliant Systems with <1.3 µS/cm Conductivity and Thermal Sanitization.

Validatable Multi-Stage Process

Our 'Ionic' multistage approach ensures sterility and chemical purity through redundancy.

01

Pre-treatment & Softening

- Removal of hardness ions (Ca²⁺, Mg²⁺) to prevent scale.

- Activated Carbon / Ultrafiltration for chlorine and organics removal.

02

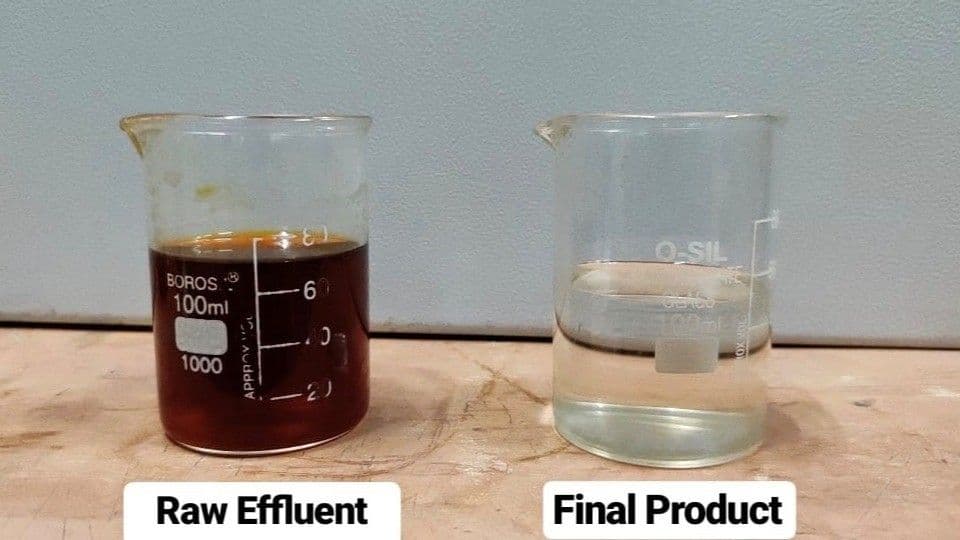

Double Pass Reverse Osmosis (DPRO)

- Pass 1: Removes >99% of dissolved salts, bacteria, and pyrogens.

- Pass 2: Polishing barrier reducing conductivity further.

- High recovery rates (75-85%) with low-energy membranes.

03

Continuous Electro-Deionization (CEDI)

- Electric regeneration of resin beds – Zero Acid/Caustic chemicals.

- Target Output: Resistivity 10–18 MΩ·cm.

04

Ultrafiltration (UF) Polishing

- Final endotoxin barrier for WFI limits (< 0.25 EU/ml).

- 6,000 Daltons MWCO ensuring complete pyrogen rejection.

Key Performance Specifications

Meeting USP/EP/JP standards for critical applications.

| Parameter | Purified Water (PW) | Water For Injection (WFI) | Ultrapure Water (UPW) |

|---|---|---|---|

| Conductivity (at 25°C) | < 1.3 µS/cm | < 1.3 µS/cm | < 0.055 µS/cm |

| Resistivity | > 0.7 MΩ·cm | > 0.7 MΩ·cm | 18.2 MΩ·cm |

| Total Organic Carbon (TOC) | < 500 ppb | < 500 ppb | < 5 ppb |

| Bacteria Count | < 100 CFU/ml | < 10 CFU/100ml | < 1 CFU/100ml |

| Endotoxins | < 0.25 EU/ml | < 0.25 EU/ml | < 0.03 EU/ml |

| Silica | – | – | < 0.5 ppb |

Advanced Engineering & Compliance

Designed for reliability, compliance, and ease of validation.

Hot Water Sanitization (HWS)

Thermal sanitization at 80°C - 85°C eliminates chemical use (Ozone/H₂O₂) and reduces validation risks.

Dead-Leg Free Design

Orbital welded SS316L piping following the '3D Rule' (<3x Pipe Diameter) to prevent biofilm stagnation.

21 CFR Part 11 Compliance

Secure PLC/SCADA control systems with uneditable audit trails for all critical process parameters.

Validation Ready

Full IQ/OQ documentation packages provided for fast-track FDA/MHRA audits.

Applications & Standards

Serving the most regulated industries.

Pharmaceutical

USP <643>, <645>

Bulk formulations, CIP, and final rinsing.

Biotechnology

EP / WFI

Buffer preparation, cell culture media, chromatography.

Medical Devices

ISO 23500

Hemodialysis and instrument sterilization.

Semiconductor

ASTM D5127

Wafer rinsing requiring ppt level purity.

FAQs: High Purity & WFI Systems

Expert answers regarding regulatory compliance and system design.

Get in touch with our experts

Have a custom requirement? Book a free consultation with our engineering team or drop us a message.

Contact Information

Call Us

020-27475272/73

020-29525874

+91 82754 86263

Mon-Sat, 9:30 AM to 6:30 PM

Visit HQ

S. No. 1, 5, 11-13, B Wing,

Mahalaxmi Heights, Mumbai-Pune Rd,

Pimpri, Pune-18, MH, INDIA.