Reactive Silica Removal Technology

Solving the Gordian Knot of Water Treatment.

Traditional silica removal is messy, expensive, or limited. Silica-Loc cuts through the complexity using advanced ceramic adsorption to remove up to 99% of reactive silica.

The "Gordian Knot" Problem

In ancient legend, the Gordian Knot was an intricate puzzle that no one could untie. Alexander the Great didn't try to untie it—he sliced it in half with his sword.

Silica is the Gordian Knot of water treatment.

Its chemistry is second only to carbon in complexity. It polymerizes, forms hard glassy scales, and resists standard ion exchange. Traditional methods like Magnesium precipitation are the equivalent of picking at the knot—messy, slow, and unreliable.

The Hidden Danger

Silica scale on turbine blades causes vibration and efficiency loss. In cooling towers, it forces high water wastage. In RO systems, it is a primary foulant that is nearly impossible to clean.

The Unconventional Solution

Old Way: Precipitation

Requires messy Magnesium salts, sludge handling, and complex pH control.

Old Way: Ion Exchange

Silica is weakly ionized, leading to early breakthrough and "dumping" from resins.

New Way: Silica-Loc Adsorption

Chemically bonds reactive silica to functionalized ceramic media, forming stable Aluminum Silicate. Simple. Clean. Effective.

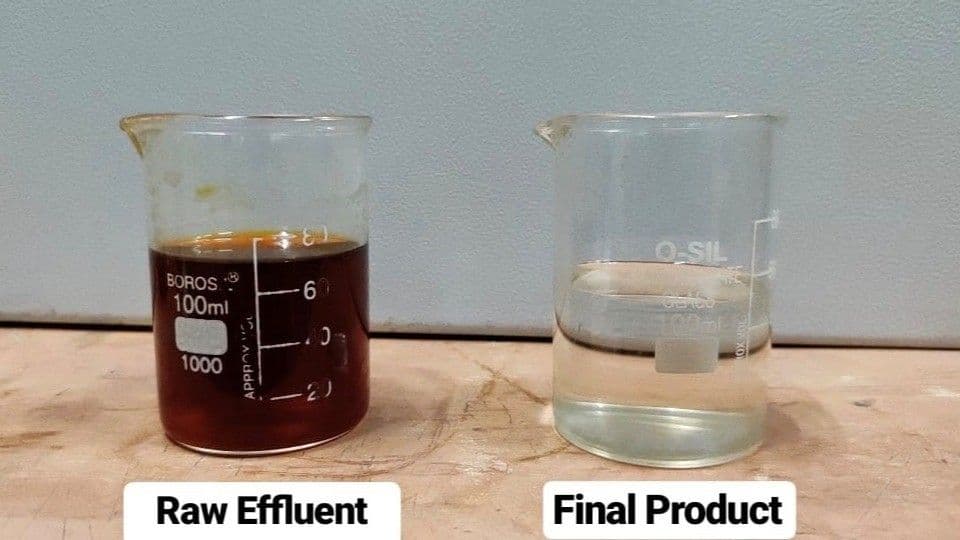

Technical Deep Dive

Engineered for Reactive Silica

Silica-Loc isn't just a filter; it's a chemical reactor in a vessel. The media is functionalized to target the difficult "reactive" silica species that pass through other systems.

High Capacity Loading

20-30%Silica by Weight

The media absorbs a massive amount of silica before exhaustion, allowing for long run times between replacements.

Superior Removal

99%Removal Efficiency

Capable of reducing reactive silica levels significantly, protecting sensitive downstream equipment.

Eco-Friendly Disposal

TCLPCompliant

Exhausted media creates a stable covalent bond, passing TCLP tests for disposal in non-hazardous landfills.

Why Silica-Loc Outperforms Traditional Methods

| Method | Primary Limitations | Silica-Loc Advantage |

|---|---|---|

| Chemical Precipitation (MgO) | Messy sludge, difficult to control, variable performance with temp. | Zero sludge generation. Simple "pump & treat". |

| Reverse Osmosis | Limited by solubility (saturation); scaling destroys membranes. | Enables high RO recovery by removing silica first. |

| Ion Exchange | Silica "dumps" upon exhaustion; competition from other ions. | Selective removal without complex chemical regeneration. |

Critical Applications

Cooling Towers

Increase Cycles of Concentration (COC) by removing the silica limit. This drastically reduces makeup water volume and chemical costs.

Boiler Feed Water

Prevent glassy scale formation on heat transfer surfaces and turbine blades. Reduce blowdown frequency and energy loss.

RO Pretreatment

Protect expensive membranes from irreversible fouling. Allows operation at higher recovery rates even with high-silica feed water.

Industrial Process Water

Essential for industries like carwashes, semiconductors, and steam injection oil recovery where silica spots or scale are unacceptable.

Operational Value

Low CAPEX & OPEX

Deployed in standard industry vessels. No complex automation, heating, or continuous chemical dosing required.

Flexible Deployment

Can be used as a stand-alone unit or a polisher. Lead-lag vessel configuration ensures continuous 24/7 operation.

Safe & Simple

No activation chemicals. No hazardous waste streams. The media is safe to handle and easy to replace.

Specifications & Feed Conditions

Essential data for engineering integration.Media Type

Alumina-Based Ceramic

Bulk Density

45 lbs/ft³

Particle Size

Nominal 18 Granules

pH Range

6.0 – 9.5

Temperature

32°F – 150°F

Flux Rate

1 – 6 GPM/ft²

Backwash Expansion

5%

Contact Time (EBCT)

10 – 60 Minutes

Feed Water Pre-requisites

Suspended Solids: Prefer Nil (Max 15 mg/L) Oil & Grease: Nil Surfactants: Nil Free Oxidants: Not Present Turbidity: < 5 NTU

Our Network

Trusted by Industry Leaders

Partnering with global organizations to deliver sustainable engineering excellence and innovative water and waste water treatment solutions.

Latest News

Get in touch with our experts

Have a custom requirement? Book a free consultation with our engineering team or drop us a message.

Contact Information

Call Us

020-27475272/73

020-29525874

+91 82754 86263

Mon-Sat, 9:30 AM to 6:30 PM

Visit HQ

S. No. 1, 5, 11-13, B Wing,

Mahalaxmi Heights, Mumbai-Pune Rd,

Pimpri, Pune-18, MH, INDIA.